Powder Coating

CMC’s long term coating experience has allowed us the ability and knowledge to diversify and offer a variety of options with endless color and texture availability. CMC’s multiple paint lines are capable of producing all types of coatings and include three overhead conveyors, eight paint booths, and oven system for both batch and uninterrupted baking times of various temperatures.

Our lines are of varying sizes and specifications so that we can accommodate virtually any coated part. Our numerous spray booths include capabilities for powder, electrostatic, conventional air spray, and air-assisted airless capabilities. Five ovens are also available for batch baking or variable speed continuous baking on our conveyor system.

Our flexibility and volume has allowed us the opportunity to coat all JASSM warheads ever produced and Hydra 70 warheads in our Hydra 70 Project.

Our Commitment

All pieces coated receive certified immersion pretreatment to ensure maximum paint adhesion. Special attention is paid to specifications. Caps, plugs, packaging and numerous post finishing treatments are available to all customers. All of our coatings utilized are purchased solely form reputable, national suppliers and military coatings are all QPL certified.

Daily our coatings are tested in house for applicable quality standards. They are verified externally through salt spray testing by independent lab, daily, weekly and montly depending on project’s specifications.

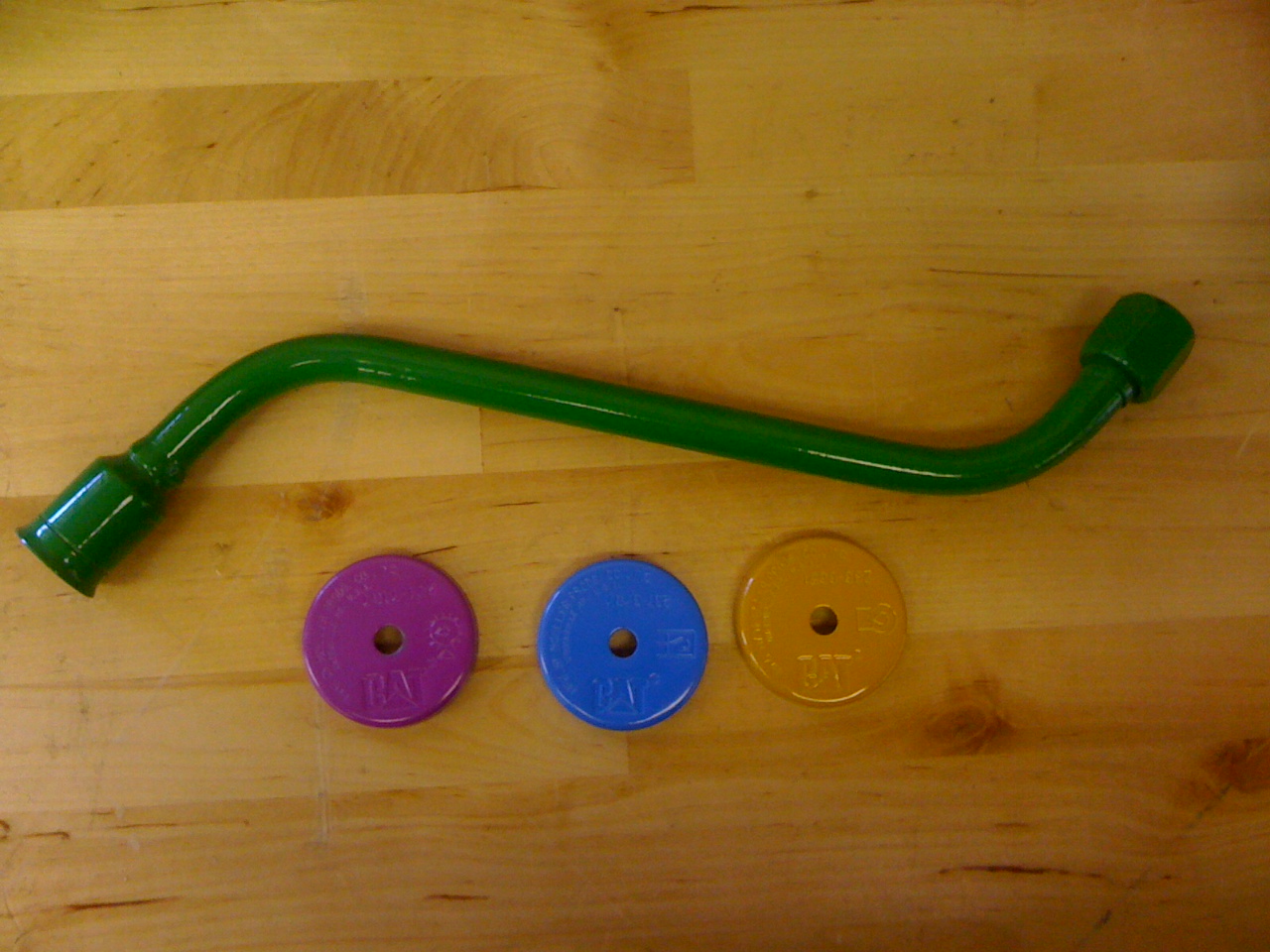

Powder Coated Parts

CMC includes technical capabilities for special masking to protect unpainted or sensitive areas and maintain critical tolerances.

On-Time Delivery

Parts are delivered on time with detailed packaging and care.

Detailed Attention

Special attention is paid to detailed prints and specifications to ensure that all parts are processed according to their specific instructions.

High Quality

ISO 9001:2008 registered company and our constant focus on zero defects ensures durable, attractive, long lasting finishes.